Electrical Switchgear Risk Assessment Study and Hazard Analysis

Electrical Switchgear Risk Assessment : In an electric power system, switchgear is the combination of electrical disconnect switches, fuses or circuit breakers used to control, protect and isolate electrical equipment. Switchgears are used both to de-energize equipment to allow work to be done and to clear faults downstream. This type of equipment is directly linked to the reliability of the electricity supply

One of the basic functions of switchgear is protection, which is interruption of short-circuit and overload fault currents while maintaining service to unaffected circuits. Switchgear also provides isolation of circuits from power supplies. Switchgear is also used to enhance system availability by allowing more than one source to feed a load.

Switchgear can be classified on the basis of voltage level in to the following

- Low voltage (LV) Switchgear

- Medium voltage (MV) Switchgear

- High voltage (HV) Switchgear

Risk assessment is the determination of quantitative or qualitative estimate of risk related to a well-defined situation and hazard.

If you use switchgear you must assess the risks and manage them to ensure safe operation and minimise the risk of injury. A risk assessment is about identifying and taking sensible and proportionate measures to control the risks in your workplace

PRINCIPLES OF Electrical Switchgear Risk Assessment

Safety-related risk assessment includes a series of steps

- Detecting the Limits and scope of use of the switchgear assembly; – design and type of switchgear and rated values – ambient conditions – Intended work procedures, besides the regular switching operations, e.g. maintenance, cable testing, work on LV control equipment

- The next step entails the examination of the associated hazards, for example those due to – electric shock – arc faults – electromagnetic fields – stored charges (electrical / mechanical) – mechanical hazards. The examination of hazards must also take into account the history of service experience, i.e. knowledge about possible minor and major failures on the equipment

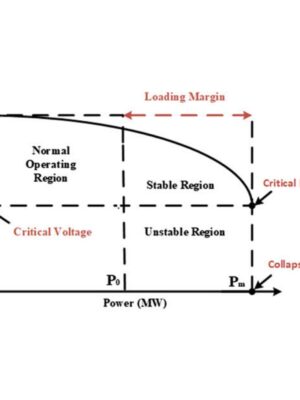

- The subsequent risk estimation considers the severity of harms and their probability of occurrence; such as the – level and extend of damage caused e.g. by arc faults – switching rate and probability of a failure on switching operation.

- Finally an evaluation is carried out to determine whether a tolerable risk has been achieved or a risk reduction through further measures is required. This can be done by using a risk graph. It is dependent on the specific industry, which risk class is tolerated in this area.

- Risk reduction implies priorities. Whenever possible the design itself should be inherently safe, supplemented by protective devices and information for the user.

ELECTRICAL SWITCHGEAR HAZARD CATEGORIES

The hazards are divided into several main categories, where each category is further subdivided describing specific sources of hazards. The complete list facilitates a thorough check whether all aspects of safety are covered.

The main categories are:

- HC 1 Essential health and safety requirements

- HC 2 Design and construction

- HC 3 Information requirements

- HC 4 Control systems

- HC 5 Guards and protective devices

- HC 6 Installation, operation and maintenance

Inspection of switchgear environment, for example the switchroom or substations, regularly is mandatory. During the inspection you should prioritise any remedial actions as follows:

- Immediate. This should always be the case when security of the substation enclosure has been interfered with.

- Earliest possible opportunity.

- Next scheduled maintenance. You should include the following items in the inspection schedule:

- Switchgear environment (switchroom access and surrounds, including fence and external walls if outdoors):

IN ELECTRICAL SWITCHGEAR SAFETY YOU SHOULD LOOK FOR FOLLOWING FACTORS

- Signs of water getting in/dampness

- Signs of unauthorised access and/or interference

- Condition of firefighting equipment and warning notices

- General housekeeping

- Signs of abnormal conditions such as high temperature, smell of hot substances or ozone, presence of smoke, signs of fresh leakage of oil or compound, distortion and evidence of sooting on enclosures

- General condition of switchgear, such as corrosion, evidence of leaks, fluid levels, presence/condition of labels, padlocks and key exchange interlocks, condition of instruments and protection equipment

- Condition of ancillary equipment such as batteries and chargers, control panels etc

ACCESSING THE RISKS in Electrical Switchgear Risk Assessment

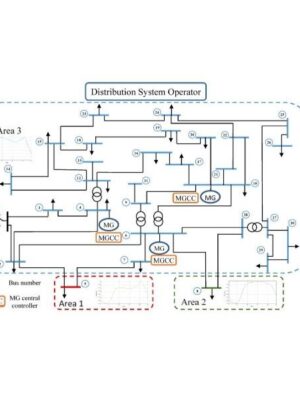

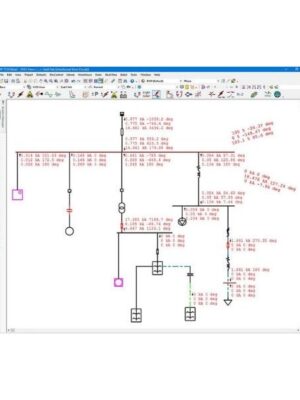

You should assess the switchgear and the electrical network to identify any potential risks and problems; the system information can help you do this

Risks and problems can include:

- Lack of maintenance

- Overstressing of switchgear

- Presence of equipment having dependent manual operation, ie where the movement of the switchgear contacts is directly dependent on the movement of the operating handle by the operator

- absence of anti-reflex control handles

- inadequate means of protection against fire

- limited access and outlet

From this assessment you will be able to identify the actions you must perform to make sure that the equipment and systems are being operated safely.

This may include:

- Prohibiting operation of overstressed switchgear when live, including disabling automatic operation to clear faults on the system. This will involve adjustments to electrical protection upstream to ensure the system remains protected

- Preventing access to the switchgear when live

- Reducing fault levels, wherever possible, by reconfiguring the network

- Prohibiting the operation of dependent manually-operated switchgear when live, except under very carefully controlled conditions

- Replacing overstressed switchgear.

Further actions you may need to take (the urgency of which will depend on the results of your assessment) could include:

- Replacing overstressed switchgear

- When possible, replacing the closing mechanism for dependent manuallyoperated switchgear. When this is not possible, you must replace the switchgear

- Fitting anti-reflex handles

- Improving measures for protection against fire. Once you have decided on the actions you will take, you must make a plan to carry them out

You decide the frequency of maintenance from factors such as:

- The type of switchgear

- Whether it uses oil, sulphur hexafluoride or vacuum interrupters

- Its age

- How often it is operated. You should also take the maintenance history of the switchgear into account.

For the assessment of the high-voltage insulation by using partial discharge measurement techniques and the evaluation of available test data and relevant standards, you need to consider the:

- Condition of the secondary wiring, protection and control equipment

- Interlocking and earthing arrangements in relation to current safety standards

- Short-circuit ratings

- Venting arrangement (where appropriate)

- Rating of the existing (fixed) equipment

The availability of spares plays a role in the decision process. You should make sure that both strategic items (eg bushings, current transformer chambers, cable boxes, operating mechanisms) and routine maintenance items (eg arcing contacts, turbulator inserts, gaskets, tripping and closing coils) are available. Do this by contacting the original equipment manufacturers, their successor companies (if the manufacturer is no longer trading) or small specialist engineering companies. Only then can you evaluate refurbishment/retrofit of the switchgear versus replacement.

METHODOLOGY FOR HV SWITCHGEAR RISK AND HAZARD ASSESSMENT

There are no risk assessment guidelines available explicitly for HV switchgear. Annex 1, Principal Elements of the Safety Objectives for Electrical Equipment, of Directive 2006/95/EC relating to electrical equipment designed for use within certain voltage limits1] Annex A, C and D of IEC Guide 116 [2] Guidelines for safety related risk assessment and risk reduction for low voltage equipment.

The switchgear assemblies are manufactured to international standards, e.g. of the IEC 62271 series where design, construction and testing requirements rule out hazards or reduce them adequately. Hence this assessment does not carry out further evaluations if a hazard is already covered by the standard. Furthermore, the hazard assessment of HV switchgear assemblies does not cover effects and/or consecutive faults, caused by the switchgear, on the power, auxiliary and/or communication networks to which the switchgear is connected. And it does not cover effects on the electrical operating area where the switchgear is installed. It concentrates on the possible hazards that the equipment itself may pose to any person in contact with this equipment

Because of the high energy levels and high voltages involved, there will always be potential hazards involved in working with medium voltage (MV) switchgear. The design and construction of MV switchgear has an important influence on its susceptibility to these arc-related accidents. Most modern switchgear is, in fact, internally arc tested, which means that should an arc fault occur, its effects are contained within the enclosure. Even in the best of equipment, however, arc-related hazards cannot be entirely eliminated. For this reason, it is important the risks are properly assessed and appropriate protective measures put in place.

Explore the comprehensive range of services offered by us for Power system Studies. Click Here!