Substation Automation System (SCADA)(SAS)

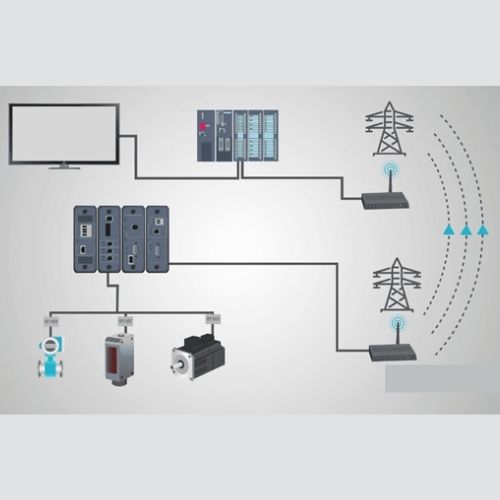

We provide Substation Automation system SCADA , SAS solutions with modern state-of-art .technologies comprising of various communication protocols. e.g. IEC61850. 1.101, IEC103. IEC104,Modbus. Modbus TCP/IP. OPC etc. System Architecture-Substation Automation.

We offer the design, engineering development of PC & Operator Panel based HMI & SCADA solutions for Substations. Switchyards, Power & Process plants.

Services Offered

• Monitoring & Control of Existing substation by collecting Input, output, Analog data points from the field via RTU / Gateway.

• Establishing Control & monitoring of various main station & substation from the centralized location to improve the quality & stability of the power system.

• Existing old station getting upgraded by installation of RTU, Local monitoring system. DCPS & Battery for the new RTU panels.

• Interconnecting Field signals with RTU & transmitting the same to Master control center New SCADA system getting online.

• Preparation of engineering documents such as SLD. control room Layout, BOM and I/O List, cable schedule and adaptation schedule, as-built drawings in PDF / CAD format.

• Panel Erection, Cable laying and Termination for existing sub-station and new sub-stations.

• Configuration, Testing and commissioning of RTU and obtaining SAT certificate from customer.

Supervisory Control and Data Acquisition (SCADA):

It is a control system architecture comprising computers, networked data communications and graphical user interfaces (GUI) for high-level process supervisory management

We have the control room for controlling the field devices integrated with RTU and control panel.

List of the devices and Panel in the Control centre are specified below:

1. Siemens RTU with two control relay panels adjacent to it.

2. One is CRP panel- ON load Tap changer

3. The other panel is the RTCC remote tap changer.4. Siemens SCADA with an operating console.

Training Session on Scada System:

We provide the training session for how to do the Configurations of field devices Input/ Output and Operate and Monitoring of Scada

We have the control center room which control and monitor the field devices and do the operation from remote location

Analyzing and optimizing the system using SIEMENS Scada.

· Basic concepts of SCADA

· SCADA application and project

· SCADA and networking

· Creating and accessing real-time and historic trends

· Interfacing SCADA via Excel, via PLC, via Relay, via Motor/LED

· Troubleshooting the application

Explore the comprehensive range of Automation Solutions offered by us Click Here!